My First venture Cable TV Business

The Ashes of Su-kam: Finding My Worth Again

The devastating bankruptcy of Su-kam hit me like a physical blow. In that dark time, a profound depression settled over me. I felt utterly worthless, the weight of failure crushing the memories of everything I had ever built. The noise of my internal critics was deafening.

Then, one day, in a desperate attempt to find a single anchor, I thought: What have I truly done? Let me just write it down. This simple act—this quiet, reflective necessity—became my lifeline. As I began to chronicle my professional journey, an unexpected surge of pride and recognition came flooding back. I wasn’t worthless. I had worked. I had created. Driven by this sudden, fierce need to reclaim my story, I started collecting old photos, dusty brochures, and scattered memories, piecing together the true tale of my entrepreneurship.

📺 The Spark of 1988: An Unforeseen Beginning

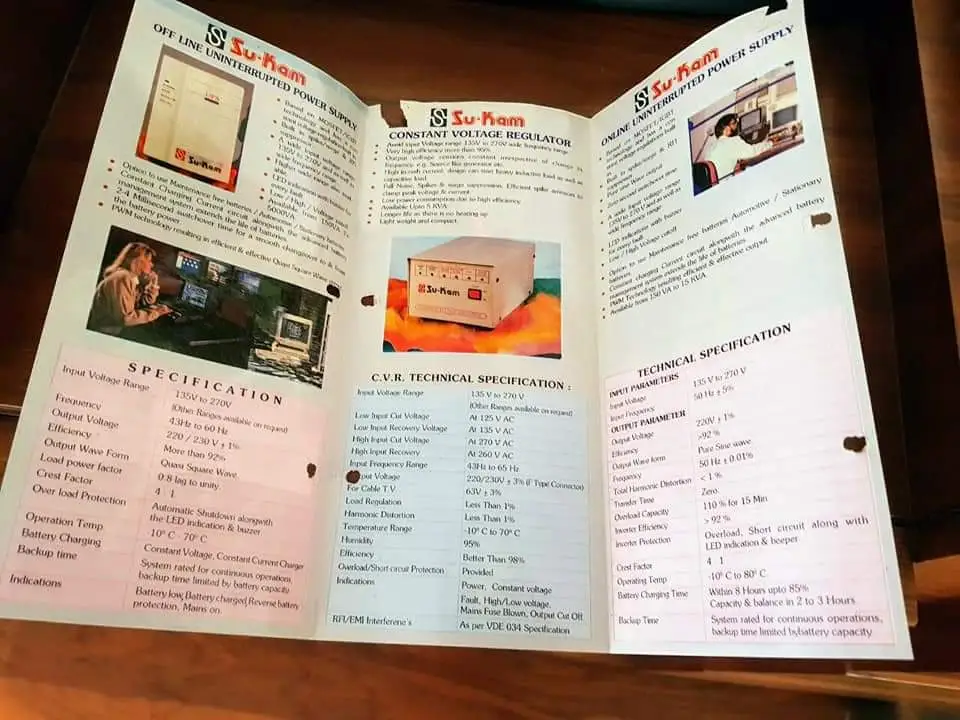

My journey didn’t begin where everyone thinks. It began in the pivotal year of 1988, a time I now look back on as the launchpad for everything. My first venture, surprisingly, was not in the realm of power inverters, the technology Su-kam is known for today, but in the exciting, innovative world of Cable TV Systems. This unexpected beginning is crucial, for it holds the key to understanding the deep roots and eventual stunning evolution of the Su-kam brand.

In those nascent days, Su-kam focused on small-scale projects that were quietly laying the foundation for our future. We concentrated on installing Master Antenna Television (MATV) and Community Antenna Television (CATV) systems, primarily for hotels and large apartment complexes. These systems were truly groundbreaking at the time. Imagine the intricacy: setting up shared antennas and VCRs capable of distributing television signals seamlessly throughout an entire building. It was a revelation! Multiple units could enjoy the same high-quality content without the immense cost of individual connections to service providers.

Recognizing the Revolution

The entertainment landscape in India was undergoing a rapid, thrilling transformation. Cable television wasn’t just a new service; it was a social and economic revolution. VCRs were prohibitively expensive, and the constant renting of cassettes was a financial drain on households. Cable TV, in sharp contrast, offered an attractive, far more economical solution. A single VCR could now entertain countless families, thanks to a cleverly designed, efficient cable network. It opened up a world of possibilities for shared, affordable entertainment.

I saw the hunger for this. I saw the market opportunity blazing bright, and I made the strategic, gut-feeling decision to pivot Su-kam entirely into the cable TV business. This pivotal shift meant delving into small-scale manufacturing, creating essential components like amplifiers, modulators, and directional couplers. This was my true entry into the world of production—an avenue to not only support our own services but to stimulate and contribute to local industry.

To make this transformation a reality, I gathered a dedicated and skilled team around me. We worked tirelessly, shoulder-to-shoulder, installing these vital cable TV systems for local providers. This initial venture was more than just good business; it was the fiery beginning of a broader, more ambitious vision—a vision that would ultimately expand and solidify into the widely recognized company that the world came to know as Su-kam.

My Su-kam Awakening: Embracing Entrepreneurship

Su-kam cable tv exhibition

Exhibition su-kam cable tv

Cable tv exhibition Su-kam

Simple Facts: Technology and Early Business Strategy

I was very ambitious and always focused on using the best technology, which was key to everything I did later. These early years were full of important steps that shaped my entire career.

Here are the main highlights of my professional career

Going to Exhibitions: From the start, I knew I needed to see what was new. I went to industry trade shows and exhibitions both in India and overseas, like in Hong Kong and Singapore. I used to save money by staying at dormitories and used to travel by foot to save money and used to get catalogues in my hand while travelling by air to save the money as I had limited money to spend but I still attended those exhibitions and during those days I always thought that one day I will also exhibit my company products in those exhibitions. This gave me great exposure to the latest technology and helped me meet important people in the industry who could become partners. today i realise how many people in my stage of business would have dared to attend those exhibitions where the money was a big challenge and hardly any resources available in those days.

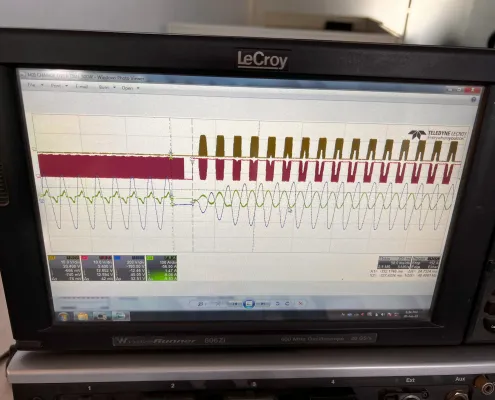

The Rare Tool and the Problem: At a Hong Kong exhibition in 1992, I was lucky enough to buy a Spectrum Analyzer (a crucial testing tool for my work) at a very low price. I remember I did not have cash but somehow arranged the money through my channels as Foreign Exchange was a rare commodity. However, getting it out of customs was another challenge I faced as there was 250% duty at that time, and the basic product cost is at their will and I was carrying a bill which was right, but I had to prove how did I got this money. So, there was a criminal case which could be registered against me at that time as I was not aware of custom rules and regulations and I had to abandon the Spectrum Analyser in the custom warehouse and was heartbroken. After 3 months I got it cleared after getting custom clearing agent. In those days custom people were more than local police people and importing anything was a big task only custom agents were able to do it for you as they had the relationship. The government red tape and the very high taxes (duties) were a major challenge that tested how determined I was.

Buying the Best Equipment: Even after the customs difficulty, I decided to invest a lot of money in a second, even better Spectrum Analyzer—the Anritsu model and other testing Equipment required for manufacturing and Research and Development work. i realised today that who would have bought Anritsu Analyser at 20 lac rupees as i could have bought house at that time with that kind of money and spent money on Spectrum Analyser. My thinking was clear that Research and manufacturing with the right testing Equipment was the most important criteria after the good engineers. getting the trained engineers was not any possibility doing the experimentation was the only way forward and to keep their morale high we needed testing equipment and we all learned together. I was committed to having the best tools.

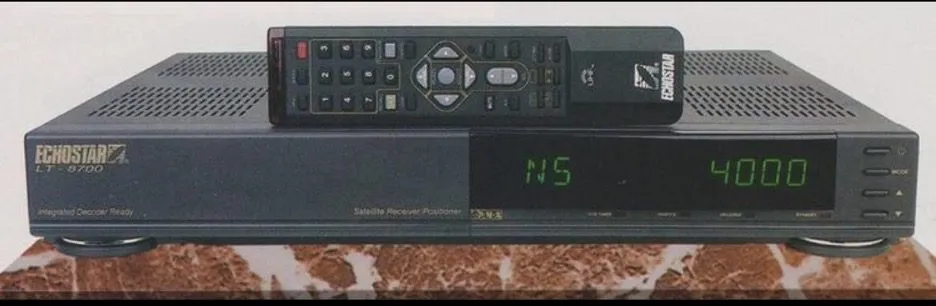

Distributing for Big Players: I got a significant boost when I secured the distributorship for EchoStar’s satellite receivers of USA based company. They were one of the biggest companies of those times as they had their own satellites and hardware to receive and distribute. This partnership was a gateway into the major broadcasting networks, especially with the government-run Doordarshan. My job involved supplying equipment and setting up Dish Antenna networks at various VVIP places as Doordarshan was the institution which used to install Dish Antennas in all Govt big wig houses and institutions. So, my Dish Antennas were installed in Prime Minister house, president house, All chief of ARMY, NAVY and AIR Chief house. Home Secretary, Defence Secretary etc were having my Dish Antennas and cable TV systems which built my reputation as a reliable supplier.

Running My Own Cable TV Service: To understand the business from the ground up, I also ran my own small cable TV service at the Subroto Park Air Force Station. I got the opportunity to run my own cable TV network and manage the subscriptions and collect the money etc. Running the local Cable TV by having a staff which was a very different experience for me at that time. As I was running a manufacturing unit and sales with hardly any staff at that time. So, I found a person with whom I created a partnership for running that business which ended up in a dispute and one day I had to leave that business. This project took lot of my time and money, but I made lot of deep contacts in Indian Air Force which helped me in later stages by getting the contracts for selling and installing cable TV systems in different Air force stations and also helped me to get the entry into Army and Navy as well. This taught me essential lessons about customer service.

The Market Changes: The 1990s brought a big change. Large national companies like City Cable entered the market. These big companies preferred to use imported equipment. This made it very hard for small, local manufacturers, including my previous collaborators, to compete. This forced me to rethink my business plan.

The Failed Digital Compression for Digital Set top box Project: As i was growing very fast in cable TV business I realised that the future is going to be of distribution of cable TV signal through the Digital compression Technology as being used in the Satellite transmission and recieving signal so I was sure that this technology is going to sweep the world one day. I was always thinking ahead of times that was one of my short coming as well as the strength. Seeing the future, I tried to develop a new digital compression set-top box by working with a Canadian tech start up company to whom i met in one of the Singapore Exhibition. I invested a lot of money in this high-tech project. As that time investing in foreign Exchange for any RnD project was a rare thinking let alone doing the same. Unfortunately, the startup team I worked with lacked the necessary experience, and the project eventually failed. This was a frustrating and costly setback of that time but that changed my thought process that creation of In house Team is more important than depending on Foreign Partner as you have no control or monitoring on them. So creation of Research and development in house team became my priority after that set back.

Echostar satellite receiver distribution in Su-kam

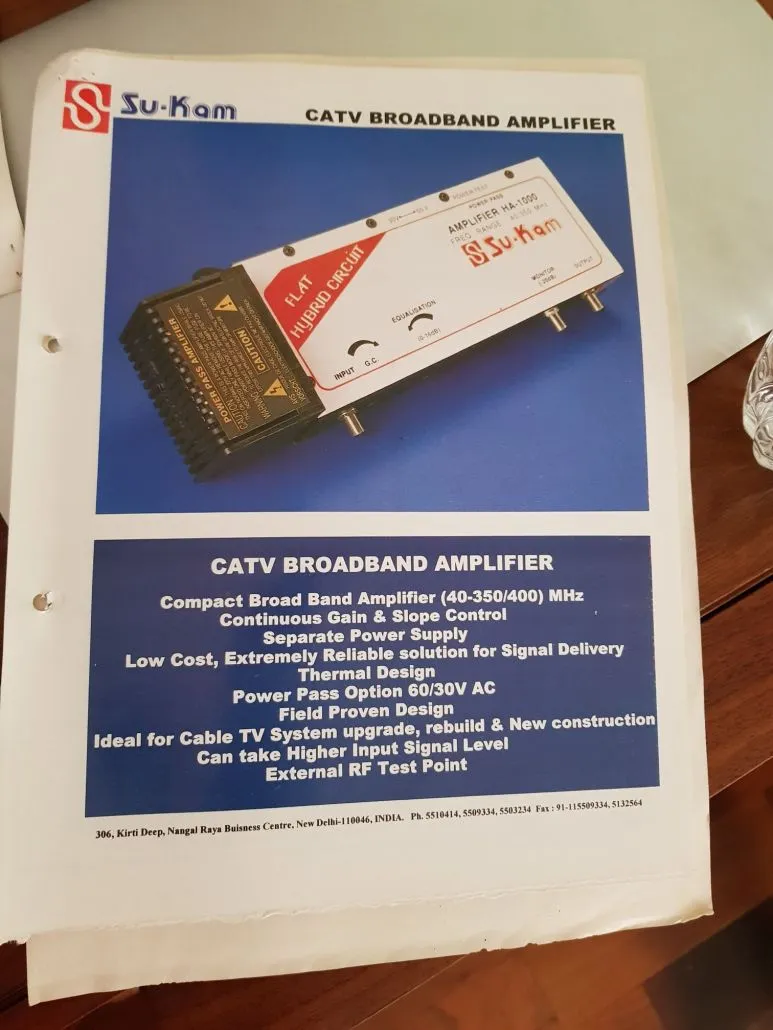

Su-kam amplifier brochure

Su-kam CATV Amplifier

Su-kam CATV Line Amplifier

The Accidental Inventor: Su-kam’s Journey

RV van fitted with Inverter

Kolkata dominated the early inverter market, with transistor-based circuits being the standard. However, I recognized the limitations of this technology and sought to innovate.

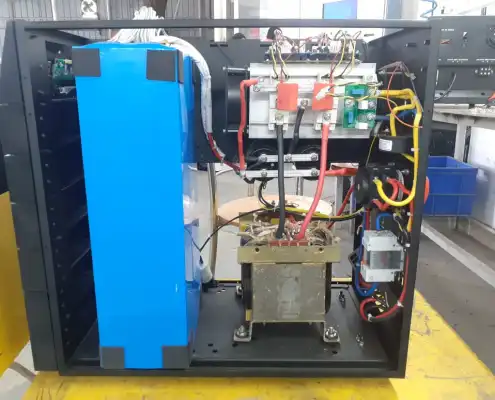

Our initial inverter design was a modular board, similar to a computer motherboard, allowing for easy repairs and upgrades. Developing a stable and functional model required extensive experimentation and iteration over two years. We faced numerous challenges, including frequent MOSFET failures and excessive noise. Through perseverance and continuous refinement, we addressed these issues and created a more reliable inverter.

A key breakthrough was the development of robust protection circuitry to safeguard the inverter from heavy loads and inrush currents. This feature, previously lacking in existing inverters, significantly enhanced durability and user safety.

Compared to transistor-based inverters, our MOSFET-based design offered several advantages. It was more compact, operated on a single battery (reducing installation and maintenance complexity), and provided more precise battery charging control.

Additionally, we introduced a distinctive black chassis, defying conventional market preferences for brighter colors. This unconventional choice ultimately became an industry standard, demonstrating our ability to challenge norms and set new trends.

First Inverter look designed by Su-kam by Mr. Kunwer Sachdev

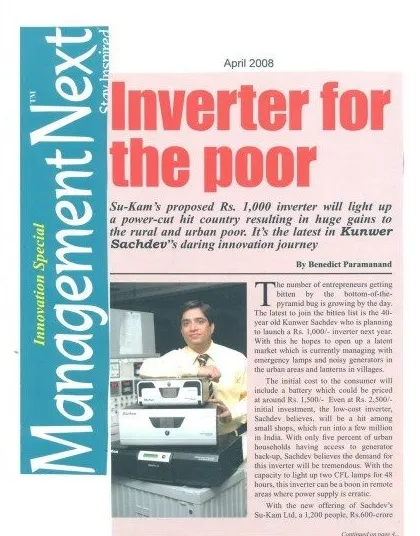

This is the first Brochure we designed and the First Newspaper News coverage of our Product

First Inverter catalogue designed by Su-kam in the Inverter industry by Mr Kunwer Sachdev

First Inverter look designed by Su-kam by Mr. Kunwer Sachdev

First newspaper news of Su-kam Inverter

First newspaper cutting of Su-kam

Initial Selling of Inverters

Establishing a distribution network for inverters was initially challenging. To overcome this, I formed a team of telemarketers who contacted potential customers using the Yellow Pages directory. I also targeted existing cable TV dealers and customers, leveraging my existing network.

Direct sales to consumers proved profitable, allowing us to control installation and maintenance. After successfully deploying 500 inverters, I gained confidence in our technology and began focusing on building a distribution network.

The primary goal was to partner with existing inverter and battery manufacturers as they possessed the technical expertise to repair our products. However, convincing these manufacturers to become distributors was not easy. I visited them, demonstrating the product’s features and highlighting its unique selling points: single battery operation, MOSFET technology, compact size, and modular design.

These features were groundbreaking, attracting attention and inspiring competitors to copy our model. However, our continuous innovation and commitment to quality ensured we stayed ahead of the curve. I oversaw customer complaints, analyzing the root causes and implementing corrective measures to improve our product and processes. This meticulous approach allowed us to refine our testing parameters and document best practices.

Second inverter model

I adopted the practice of naming our inverter models, which led to some becoming well-known. However, I missed an opportunity to create independent brands for these models, separating them from the Su-kam umbrella. This approach would have enhanced brand differentiation and reduced confusion among consumers.

Additionally, our focus on model names overshadowed the broader brand and product categories, creating challenges for consumers and hindering effective marketing.

One notable innovation was introducing a digital display, a first in the industry. This feature provided users with a clear overview of all inverter functions. At a time when LCDs were a rarity in inverters, our achievement was significant.

Electronic generator by Su-kam

Setting up the R&D

Recognizing the importance of innovation, I established a small R&D centre. Over time, this team expanded as we invested in testing equipment and dedicated resources to technological advancement. However, building a capable R&D team proved challenging, as finding experienced engineers who could independently develop new products was scarce.

I encountered resistance to experimentation and failure within the Indian engineering culture, where job security often took precedence over innovation. I worked diligently to foster a mindset that embraced risk-taking and learning from mistakes.

While I successfully created a culture of innovation and product development, I regret failing to instil a sense of ownership in the R&D team. Many engineers lacked pride in their creations and struggled to see the impact of their work, which hindered their motivation and potential.

Leadership and team dynamics were additional challenges within the R&D department. Finding a suitable leader was difficult, and I often found myself taking on managerial responsibilities. Despite efforts to hire and train new talent, many left due to a lack of strong leadership and a culture of nepotism.

My experience in R&D taught me valuable lessons, including the importance of continuous learning, fostering a collaborative environment, and addressing the challenges of managing experienced engineers. I observed firsthand how a fear of change and a focus on maintaining one’s position can hinder both individual and organizational growth.

One notable example of my approach to innovation was addressing a customer complaint about inverter overload. Introducing a multi-stage overload protection system gave customers more flexibility and control, preventing accidental shutdowns.

Through my experiences, I realized that many engineers lose their drive and curiosity once they achieve job security. They may become complacent, neglecting personal growth and failing to adapt to changing technologies. For instance, an engineer who relied on outdated Assembly language programming hindered the team’s progress and created challenges for new engineers.

In India, a prevalent challenge is the tendency of individuals to hoard knowledge and avoid sharing information. This mindset creates silos and hinders collaboration. Overcoming these cultural barriers is essential for building effective R&D teams.

My journey in R&D has equipped me with valuable insights into technology development, team management, and overcoming organizational challenges. These experiences will be invaluable as I continue to lead and innovate in the future.

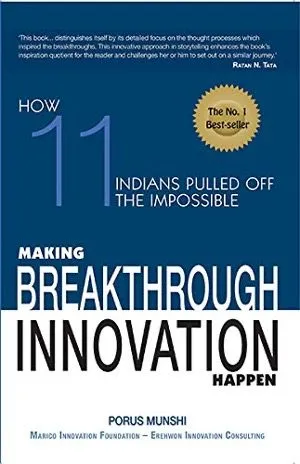

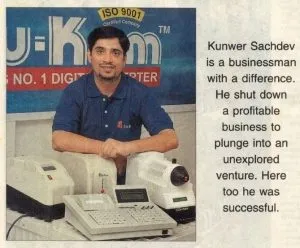

Books written Kunwer Sachdev

Porus Munshi’s book, “Making Breakthrough Innovation Happen,” challenged me with insightful questions about fostering R&D and innovation at the time. Initially, my understanding of innovation was limited. However, through this experience and my dedication to building a culture of innovation in India, I’ve become a more well-rounded individual. I’ve also honed my interpersonal skills, which will be valuable when I write my book on fostering innovation within organizations. Innovation, I’ve learned, transcends R&D, permeating every aspect of life. It’s all about shifting mindsets and embracing change – the only constant. Notably, three different authors have included a chapter about me in their books, reflecting how my knowledge, experience, and perspective have evolved. As I continue to learn and grow, I wouldn’t be surprised if an entire book is dedicated to my experiences in the future.

I still remember that the efforts put in by the VVDN founders to collaborate with us were phenomenal. They are the founders of a company called VVDN, and they visited my RnD and wanted to collaborate with us on many projects. I was also interested in doing the same, but in our RnD, the culture of collaboration needed to be added, and today, VVDN has become such a big company.

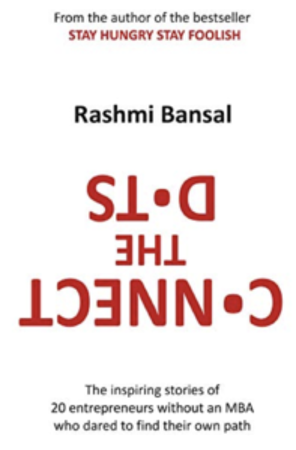

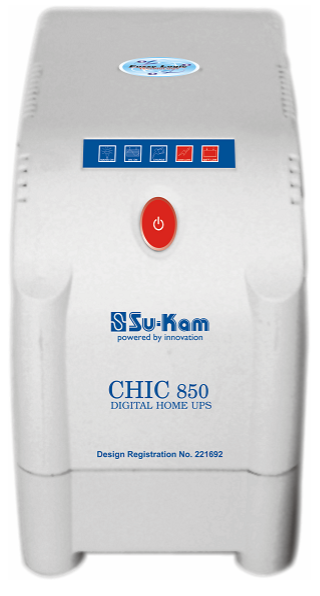

Innovation Drives Success: The Chic Inverter Story

Following our successful market penetration in 2002, we strategically increased pricing by introducing subtle aesthetic and functional enhancements, solidifying our brand’s position in the market.

A pivotal moment in our product development was the creation of the plastic inverter. Inspired by customer complaints about the safety hazards of metal inverters, particularly in damp conditions, we decided to design a safer alternative.

Overcoming initial scepticism from our R&D team, we developed a plastic inverter that could withstand the high temperatures generated by the internal circuitry. By incorporating a temperature sensor and making necessary circuit modifications, we ensured the inverter’s safety and reliability.

The GE plastic division played a crucial role in providing the innovative PC ABS material, which was relatively new to the Indian market. We named the product “Chic,” a term associated with beauty and appeal, reflecting our confidence in its design.

The launch of the Chic inverter was a resounding success, marking a turning point in the industry. The product’s innovative design and attractive name contributed to its popularity, demonstrating the power of effective branding.”

Chic inverter model by Su-kam idea of Mr. Kunwer Sachdev

First plastic Inverter by Su-kam

Whenever I created any product or model, I always gave a name to it. So I made a lot of model names, and a few of the models acted as brands in themselves. This Chic Inverter became such a big hit inverter model that India Today gave us an innovation award. It was said to be the decade’s innovation in India. We launched this Inverter in 2003; most customers have used it for over 20 years.

Now another situation arrived: plastic granules were being imported from outside India, and metal was becoming very cheap. It was getting out of our hands, and margins were shrinking, so we wanted to shift to metal which became a challenge as our identity became plastic InverterInverter.

In 2003, I started working on a plastic inverter called Chic. It took one year for me to develop that model with the help of the international company GE Plastics. After many designs and changes, we made a superior-grade plastic that could withstand 120 degrees Celsius.

Here I want to mention another fact, when we launched this product, one of our competitors found the exact look inverter in Plastic by copying our design, which started burning into the market. He got a bad name, and later on, we filed a case against them in court, and we lost as they proved in court that we filed the design patent after launching the product, which was the first lesson learnt by me in the Intellectual Property rights as this was my first direct fight on IP.

Inverter – Fairy Queen: A Journey of Ambition and Lessons Learned

Building on the notable success and positive reception of our Chic inverter model, we proudly transitioned into the realm of creative innovation with the introduction of the FairyQueen model. This unique inverter was artistically designed to resemble a locomotive engine, infusing a sense of nostalgia and charm into the modern home environment. The FairyQueen was not merely a functional appliance; it was intended to be a stylish and visually appealing addition, particularly aimed at enhancing the aesthetics of bedrooms and personal spaces, making them not just functional but also delightful places of relaxation and inspiration.

However, despite our best efforts involving extensive testing, rigorous validation, and meticulous planning, the launch of the FairyQueen encountered a significant hurdle: packaging issues. This unforeseen oversight in the packaging design and execution led to numerous damaged products during shipment. Consequently, these incidents resulted in a palpable loss of customer confidence and trust in our brand. What was meant to be a triumphant entry into the market turned unexpectedly sour, serving as a stark reminder to our team about the paramount importance of meticulous attention to detail across all facets of product development, particularly in the face of prior successes.

While the FairyQueen’s innovative design and aesthetic appeal were undoubtedly striking and would have set new standards in the market, the unfortunate packaging flaw became an insurmountable obstacle that overshadowed its launch. This model’s failure proved to be a significant setback for our company, yet it simultaneously offered valuable insights and lessons regarding risk management. We learned the critical importance of comprehensive quality control processes and the vital role that effective packaging plays in ensuring customer satisfaction and the overall success of a product. As we move forward, this experience will serve as a foundational pillar guiding our approach to future launches, as we aim to harmoniously blend innovation with dependability in our product offerings.

Beautiful Fairy Queen Inverter in the image and also Point of Sales I made in the year 2004 as all thePoint of Sales POS were being imported at that time, and I wanted to make it in India and sell it at a cost-effective pricing with Indian customized features and sold more than 100 pieces but somehow couldn’t make it a success.

Revolutionizing Inverters: India’s First Sinewave Technology

Our initial inverters generated a square wave output, causing a bothersome humming noise in appliances and reducing their lifespan. Determined to offer a better solution, I embarked on a challenging journey to develop India’s first sinewave inverter.

Initially, we faced internal resistance. However, by creating two R&D teams and offering equal rewards, we sparked healthy competition. One team, led by a newly hired engineer, built a prototype using DSP technology. While this version had limitations, it paved the way. Through collaboration and perseverance, the existing team developed a more reliable single-battery sinewave inverter based on a standard microcontroller within a year.

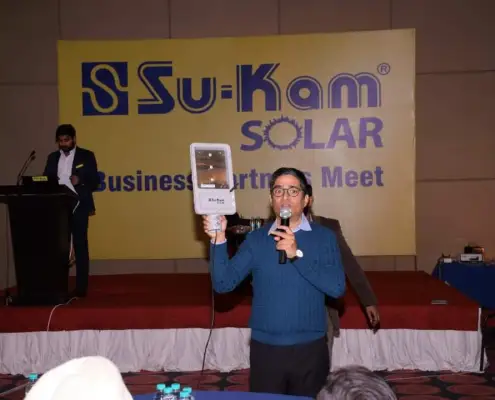

Marketing this innovative product presented another hurdle. Dealers weren’t familiar with sinewave technology. To bridge this gap, I organized dealer meetings, personally demonstrating the benefits using testing equipment. This hands-on approach, combined with the significant achievement of creating the first indigenous sinewave inverter, resonated with dealers.

Building on Innovation and Risk-Taking

This success fueled our export ambitions, as China lagged behind in this technology at the time. Looking back, I realize my natural tendency to embrace risk and explore new avenues. While many in India were risk-averse, I thrived on pushing boundaries. This passion for innovation became the cornerstone of my work, shaping not just our inverters but also my personal life.

Small UPS for Desktop Computers

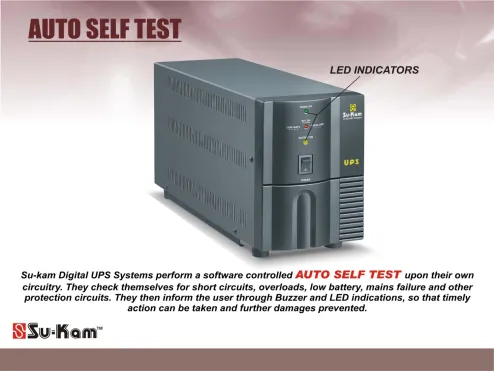

“We pioneered the development of compact UPS systems specifically designed for computers. Our early models, introduced around 2003, offered extended backup times, catering to the growing demand for reliable power solutions. We were also the first in India to produce pure sinewave UPS, a significant technological advancement.

However, despite our innovative contributions, we faced challenges in establishing a distinct distribution channel for UPS products. This oversight limited our market penetration, preventing us from receiving the recognition we deserved for our technological achievements.”

In 2004, I ventured into a new market by developing domestic point-of-sale (POS) systems. This was a departure from the imported models dominating the market at the time. While successfully selling over 100 units, I ultimately faced challenges in scaling the business.

The lack of a dedicated sales, service, and R&D team proved to be a significant obstacle. This experience taught me valuable lessons about the importance of focused business strategies and specialized teams for long-term success.”

A Tale of Innovation: Our Solar Home Lighting Journey

Inspired by the widespread adoption of Chinese solar home lighting systems abroad, I sought to create a superior alternative. Upon returning to India, I presented my R&D team with a sample and challenged them to develop a more reliable and feature-rich system.

We successfully designed a product with multiple lights, a radio, and mobile phone charging capabilities. However, the initial design lacked aesthetic appeal. Through iterative design and development, we eventually created a visually appealing and functional product.

Despite our technological advancements, market challenges hindered our success. The ecosystem of suppliers was not conducive to innovation, and the company faced significant development costs. Additionally, internal factors, such as a lack of alignment between sales and marketing teams and a focus on individual advancement rather than company goals, hampered our efforts to promote the product effectively.

While the solar home lighting system had the potential to establish India as a leader in this field, its commercialization was hindered by these obstacles.”

Birth of Home UPS

I championed the development of innovative technologies, including the groundbreaking Home UPS. Launched in 2005, this product revolutionized the industry by offering seamless switchover between grid power and backup, ensuring uninterrupted operation of computers and TVs.

Despite facing challenges related to material costs and internal resistance, I persisted with the Home UPS project. We addressed cost concerns by introducing a new model with a metal chassis and plastic front while maintaining our premium positioning.

To further differentiate the Home UPS, we implemented a unique feature that allowed users to select between computer and standard load modes. This innovative technology and a strategic reduction in sales tax positioned the Home UPS as a compelling alternative to traditional inverters.

Despite initial scepticism from competitors, the Home UPS’s superior performance and benefits quickly gained traction. Within a year, the industry adopted the term “Home UPS” to describe similar products, acknowledging Su-Kam’s pioneering role.

The Home UPS became a defining moment in Su-Kam’s history, demonstrating our ability to drive industry change through innovation and strategic thinking.”

Innovation with LED indications

Our initial LED indicators were fundamental, but we envisioned leveraging inverter technology for a more informative display. Inspired by aviation technology, we developed a cost-effective solution that displayed charging and battery status. One day, I was travelling to Mumbai from Delhi, and it sparked in my mind why not use this kind of image in our Inverters and UPS. I started working on the ways with my RnD team, and we developed a prototype for this kind of display, making it very cost-effective.

This innovation quickly became an industry standard as competitors imitated our approach. As that time I did not got this design patented so every one in the industry copied that idea and it became the industry norm.

While we faced challenges in perfecting certain technologies, our focus on quality and reliability established Su-Kam as a trusted brand. Our products’ durability and low maintenance requirements, while initially frustrating dealers who relied on after-market services, ultimately solidified our reputation.”

Power guard for homes and offices

I spearheaded the development of a revolutionary power protection device designed to replace traditional stabilizers. This innovative product offered superior protection against voltage surges, dips, and fluctuations, safeguarding valuable home and office appliances.

We successfully introduced this technology to the market, creating significant demand both domestically and internationally. Recognizing the growing need for advanced power protection in urban areas, we also developed a Wi-Fi-enabled Power Guard. However, despite its potential, this product failed to gain traction due to market conditions and timing.

The Power Guard, designed to protect against voltage variations and spikes, was ahead of its time. As power quality improved in many cities, the immediate need for such a device diminished. Nevertheless, we offered two models—a compact 6-amp version for smaller appliances and a 16-amp model for air conditioners—to cater to diverse customer needs.”

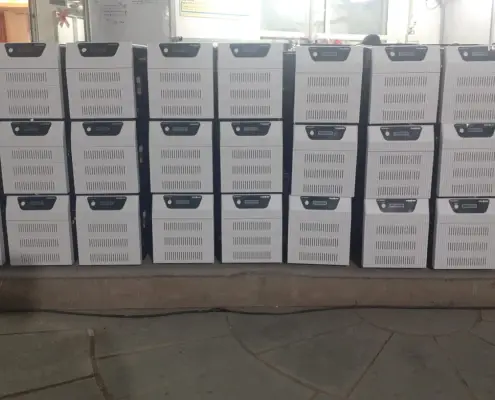

Designing of high-capacity inverters

The success of our small inverters disrupted the market for small generators. To capitalize on this momentum, we embarked on a challenging journey to develop high-capacity inverters.

Lacking existing models or blueprints, we turned to our online UPS technology for inspiration. Despite difficulties in acquiring IGBT components, we successfully designed and built a 5KVA IGBT-based inverter.

Scaling up to higher capacities presented new challenges, particularly in terms of battery management and installation complexity. The sheer size and weight of these inverters, coupled with the need for frequent battery maintenance, made installation difficult for traditional dealers.

To address these issues, we established a dedicated service team to handle installation and maintenance. However, training dealers proved challenging, as many lacked the necessary expertise. The complexities of installing high-capacity inverters often lead to conflicts between dealers and customers.

Despite these obstacles, we continued to develop higher-capacity inverters, focusing on improving efficiency and reliability. While I was unable to complete certain projects during my time at Su-Kam, our innovations laid the groundwork for future advancements in the inverter market.”

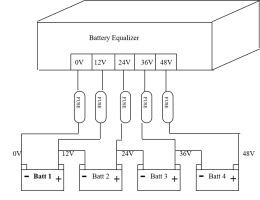

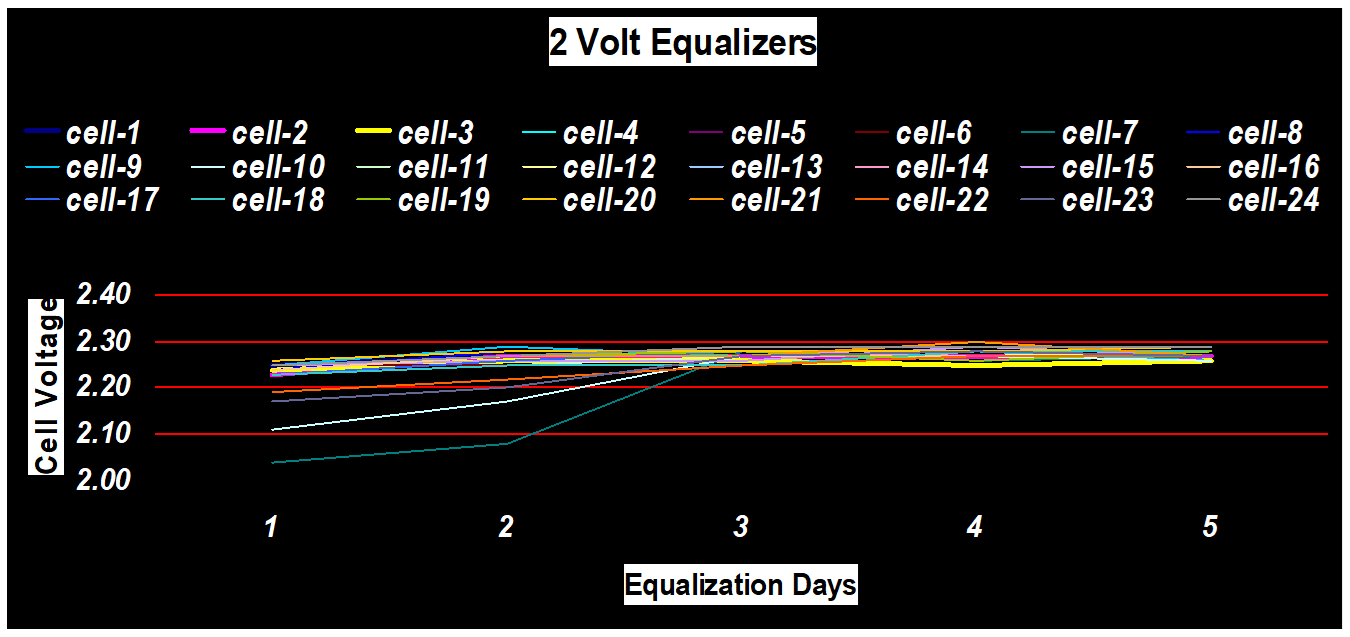

Battery Equalization for Lead Acid Batteries and called BMS for Lead Acid Battery

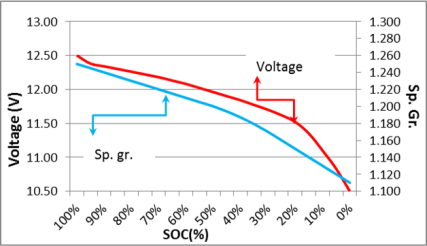

Our Battery Management System (BMS) was a pioneering solution for the inverter UPS industry. Developed in 2005, it addressed the common problem of battery bank imbalance, significantly reducing battery life.

I initially recognized this issue when testing inverters at my home. Despite using four high-quality batteries, I experienced premature failures due to mismatched battery ages. This led us to develop the BMS, which ensures equalized charging and discharging, prolonging battery life.

While the BMS was initially met with scepticism, particularly among dealers who preferred using single batteries, its benefits became evident. We successfully implemented the BMS in various applications, including golf carts and telecom towers, demonstrating its effectiveness in managing diverse battery types.”

Power On Wheels demo Truck for showing high capacity Inverter.

To showcase our advanced inverter technology, we created a mobile demonstration unit: the Power On Wheels truck. Despite logistical challenges, including a heavy battery bank and limited truck capacity, we successfully used this platform to promote our inverters across India.

While the Power On Wheels truck served as a valuable marketing tool, it faced operational difficulties, such as frequent battery failures. These issues hindered our ability to consistently demonstrate the inverter’s capabilities, limiting its effectiveness in attracting generator sellers.

Despite these setbacks, the Power On Wheels truck played a significant role in raising brand awareness and informing the market about the potential of large-scale inverters.”

Touch Screen PCU

Our pioneering touchscreen solar PCU, a groundbreaking innovation at the time, was unfortunately hindered by a critical software flaw. Despite significant investment and external expertise, this oversight prevented the product from achieving its full potential.

The touchscreen interface, a feature that would have revolutionized the industry, was compromised by the software issue. While we successfully developed and deployed a limited number of units, the product’s overall performance was hindered.

This setback was particularly disappointing given the potential for international market penetration. The touchscreen technology, as demonstrated by the success of Apple products, had the power to transform the industry. Unfortunately, our failure to address the software issue prevented us from capitalizing on this opportunity.”

Matrix Inbuilt Inverter

We designed an Inverter with a builtin SMF battery and this model was very heavy as it had 150AH SMF battery was built in and transportation was a challenge and batteries didn’t last long.

Tractor Inverter

Collaborating with Escorts Tractors, we developed a specialized inverter designed to integrate seamlessly with their tractors. This innovative solution aimed to address the critical issue of power shortages in rural areas.

The inverter, engineered to withstand harsh environmental conditions, was IP67 compliant and capable of operating in dusty and muddy environments. By connecting the tractor’s battery to the inverter, farmers could access reliable power for their homes and fields, even in remote locations.

This groundbreaking technology offered farmers a convenient and sustainable power source, empowering them to overcome the challenges of limited grid access.

Lauch Of Automotive batteries

Automotive batteries

Our innovative automotive battery range, developed over a year, successfully penetrated the market. However, we encountered significant challenges in providing adequate after-sales service.

The service team, comprised of a mix of experienced and inexperienced personnel, struggled with internal conflicts and a lack of leadership. These issues, coupled with outdated systems and processes, hindered our ability to deliver effective service.

The decline in service quality negatively impacted our brand reputation and customer satisfaction. Despite our technological advancements, the failure to provide reliable service ultimately limited the long-term success of our automotive battery business.”

Automate Truck and Tractor Brochure

Telecom inverter

Our telecom inverter, designed to replace generators in tower installations, offered a promising solution. However, the project was ultimately hindered by the poor quality of SMF batteries manufactured at our Baddi facility.

Despite the inverter’s potential, the unreliable batteries limited its effectiveness. This setback represents a missed opportunity to establish a strong presence in the telecom market.”

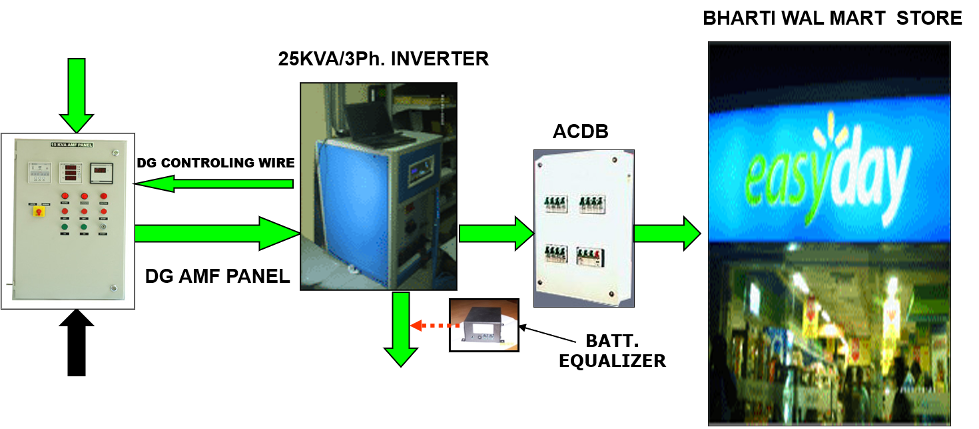

The Easyday stores power backup, a joint venture between Bharti and Walmart.

Our custom-designed inverters for Walmart stores integrated seamlessly with generators to provide reliable backup power. Despite the project’s success, we faced challenges in executing it due to a lack of dedicated project teams.

The Walmart project, which required innovative solutions to space constraints, showcased our ability to deliver tailored power solutions. However, internal coordination issues, exacerbated by my frequent travels, hindered the project’s completion. Despite efforts to revive it, the project was ultimately abandoned, leading to a loss of reputation and missed opportunities.”

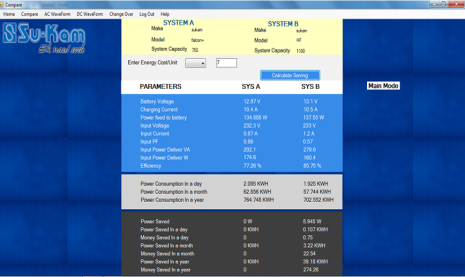

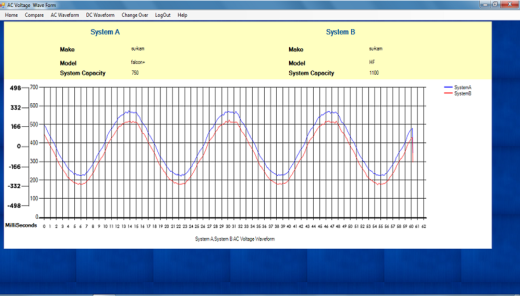

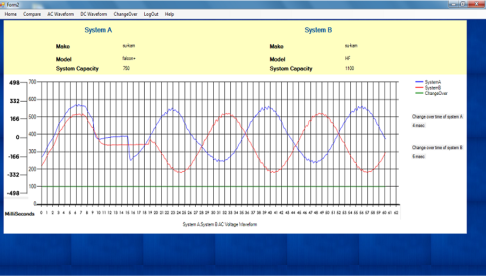

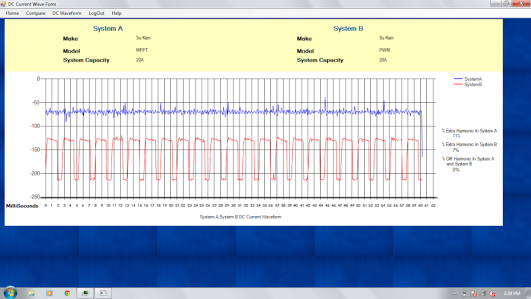

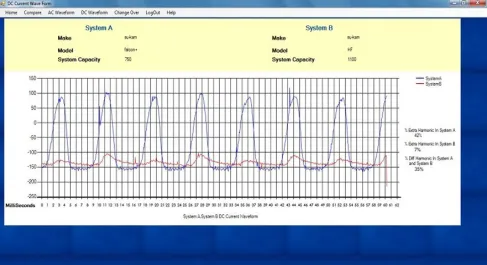

Electroscopie for comparison of two UPS/Solar products

Due to industry perceptions, our superior technology often went unrecognized. To address this, we developed a comprehensive comparison tool that would objectively demonstrate the benefits of our products.

Despite the technical challenges of creating and deploying this tool, we successfully developed a device capable of showcasing performance metrics across various parameters. However, we faced additional obstacles in training our sales and service teams on its effective use.

While the comparison tool had the potential to revolutionize the industry, particularly in the context of home appliances, its ultimate impact was limited due to internal challenges and missed opportunities.”

Solar water Pumping System

Our innovative solar water pumping solutions aim to address the energy consumption challenges faced by rural areas. We were on the verge of completing a versatile system that could operate on both AC and DC power, eliminating the need for batteries in certain scenarios. Additionally, the system was designed to feed excess solar energy back into the grid

Unfortunately, the development of this promising technology was cut short by the NCLT proceedings.”

Battery Water Topping Kit

Battery Water Topping Kit

“I developed a battery water topping kit to address the safety and maintenance challenges associated with traditional battery filling methods. This innovative tool aimed to eliminate the risks of acid spills and streamline the process.

Despite significant investment and development efforts, the battery water topping kit failed to gain traction in the market. This setback can be attributed to various factors, including ineffective marketing and a lack of awareness among consumers.”

Water Topping Kit Brochure

Online UPS

“As early as 2006, we pioneered the development of online UPS systems. While we achieved significant success with our traditional galvanic isolation technology, the market was shifting towards higher-efficiency, lightweight high-frequency inverters. Our double-conversion technology, while reliable, was less efficient than the triple-conversion solutions offered by international competitors. Despite our continuous efforts, the demand for our traditional online UPS models waned, as the market increasingly favored the more advanced high-frequency technology.”

technology for selling so we kept selling in small numbers in Su-kam. We could have improved the technology as per the changing times, but we were not able to do the same.

Investment from Reliance and Tamesk

A significant turning point for Su-Kam came in 2005 when we secured a $10 million investment from Reliance Power Fund. This substantial funding, unprecedented in the inverter industry at the time, marked a shift in investor perception towards Indian manufacturing companies. The dot-com bubble had created a favorable climate for investments in promising ventures, and Su-Kam’s strong brand and potential for growth made it an attractive target.”

At that time, investors told me to go and acquire one US company in the same space.

I went with one of the investor team members to the US. I saw a US company functioning for the first time and realized that we are good in certain aspects but must improve in other areas. I got a lot of sample documents to help me create better standards in the organization, especially in the RnD.

Our deal didn’t mature, but my learning was tremendous as I got so much exposure to how the Western world thinks and functions. It always helped me, and I kept learning things from the people I made friends with during my visit.

Solar PCU for Offgrid Solar application

We were the first company in India to produce solar electronics and solar batteries in India and made a lot of good products and sold them to dealers and distributors and created a brand to be a solar company. As there was continuous development happening so we worked with various state govts to create the specifications of the projects like TEDA, UPNEDA, and other state govts along with the MNRE which was under central govt trusted our company to give them the innovative products required by different state govts.Also made solar charge controllers for different capacities using PWM and MPPT technology before any one else could make it in India but somehow we couldn’t make it successful in India offgrid solar systems as showing savings to the customer with Lead Acid battery was not possible. Still most of the companies are selling these systems in India with a lot of dissatisfaction of the customer where customers want to save the money.

PreviousNext

These systems were developed by us 10 years back for various State Govt projects and that time the requirement was for increasing the back up through solar and in PCU the battery is charged through Solar and discharged when the back up is required so the battery life comes in to the picture and the solar power is stored in to the battery and than utilized from the battery only and in this process battery cycle is reduced. As it’s the Lead Acid battery can give you limited no of cycles and maintenance of Lead Acid battery is another headache.

So this technology is useless in the present timing for the Indian conditions as the power has improved in most of the areas and customer want to save the power bill through the solar system which is not possible by this technology.

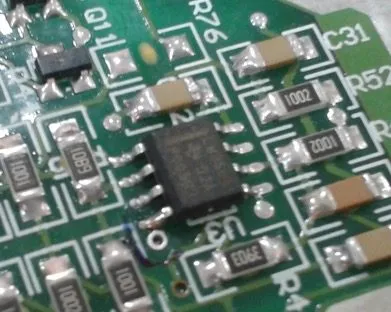

SMD based- Inverter and UPS PCBs

Recognizing the future trends in electronics, I foresaw the shift towards SMD technology. Despite initial skepticism and rumors about its unreliability, I was convinced that SMD technology would revolutionize the inverter industry.

We successfully transitioned our products to SMD technology, resulting in improved reliability and cost-effectiveness. While domestic competitors initially resisted this change, the market eventually embraced SMD as the standard.

Our early adoption of SMD technology not only enhanced our domestic competitiveness but also positioned us for international success. By offering superior products with advanced technology, we challenged the perception of Indian manufacturing capabilities and gained a competitive edge in the global market.”

Aluminum Transformer Design for inverters and UPS

“The introduction of aluminum transformers marked another significant milestone for Su-Kam. Recognizing the industry shift towards aluminum technology, we developed our own transformer designs that incorporated both copper and aluminum.

This innovative approach, which enhanced transformer efficiency and durability, was met with resistance from competitors who spread misinformation. Despite these challenges, the industry eventually embraced aluminum transformers, acknowledging their superior performance.

We further differentiated our products by introducing a unique battery terminal design that eliminated the need for soldering. This innovative approach improved reliability and reduced manufacturing costs, setting a new standard for the industry.

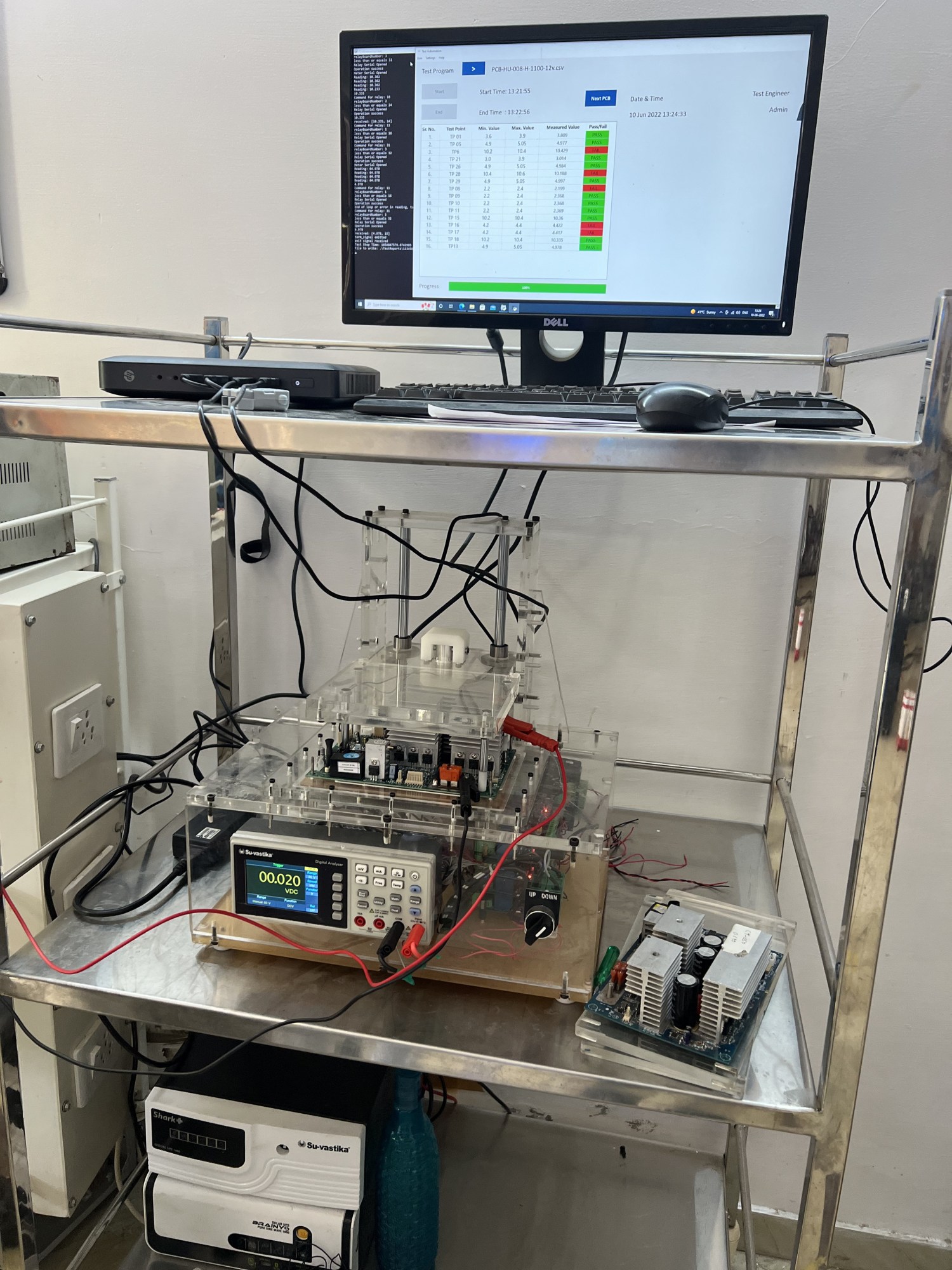

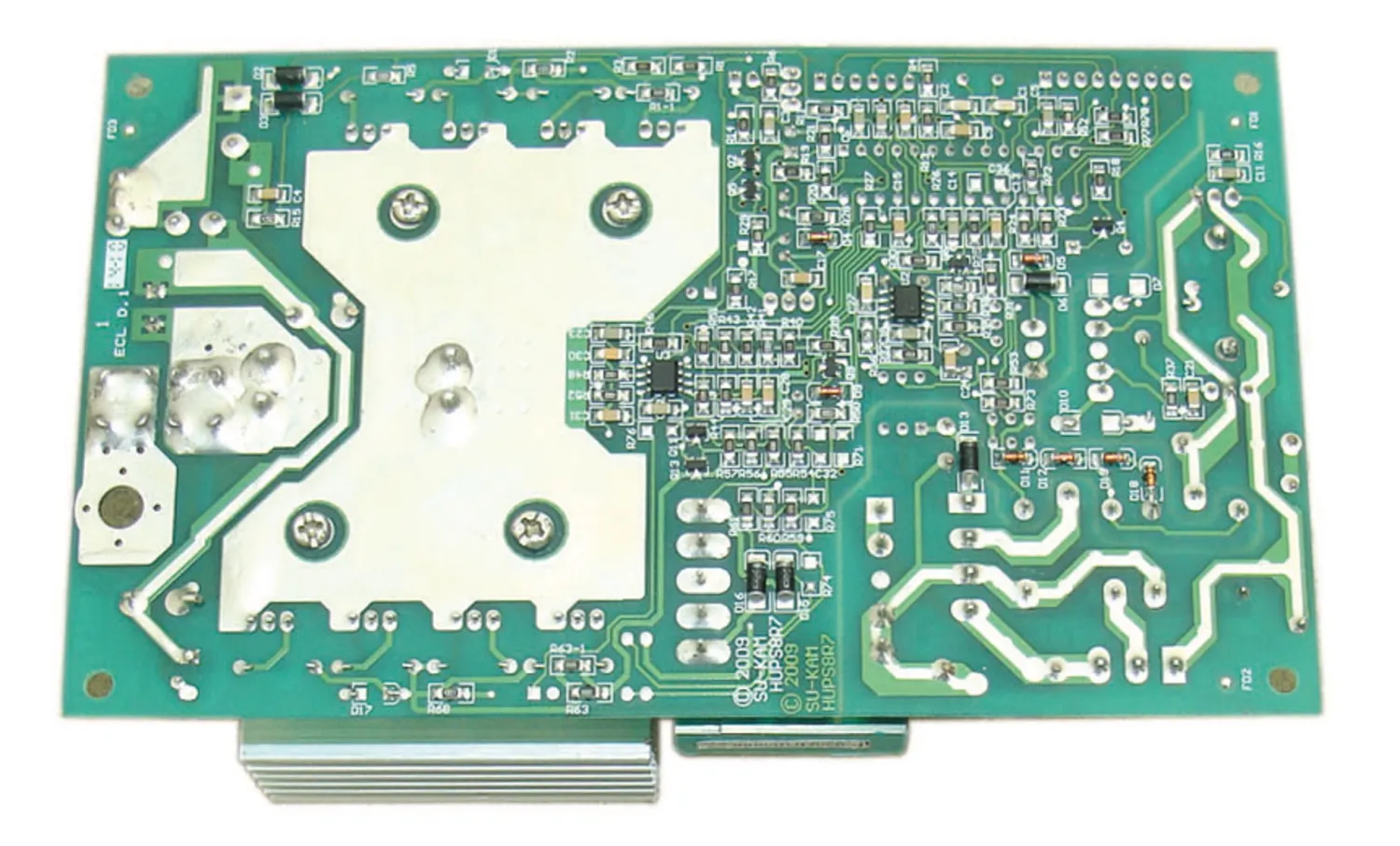

Automatic testing Jigs for Testing of complete Product Range

“I envisioned automating the testing process for our products, encompassing PCBs, transformers, and final inverters/UPS units. Despite years of effort and investment in a dedicated R&D team, this project ultimately stalled due to a lack of cross-functional collaboration and a focus on product development over implementation.

While our R&D team successfully designed the testing jigs, the transition to production proved challenging. The lack of ownership and alignment between R&D and other departments led to delays and inconsistencies. This hindered our ability to launch new products and effectively market them to dealers and distributors.

The testing jigs, which could have significantly improved efficiency and quality control, were underutilized due to various factors, including a lack of training and inadequate validation. This missed opportunity highlights the importance of a holistic approach to product development, encompassing design, testing, and implementation.”

Our affordable 100VA inverter with an integrated SMF battery was designed to cater to the needs of low-income individuals and small businesses. Priced below ₹1,500, this product gained significant popularity in India and international markets.

Despite its success, the inverter was limited by the relatively short lifespan of its SMF battery, which often failed within a year or two. This challenge hindered the product’s long-term viability, particularly in regions where replacement batteries were difficult to obtain.”

Our affordable 100VA inverter with an integrated SMF battery was designed to cater to the needs of low-income individuals and small businesses. Priced below ₹1,500, this product gained significant popularity in India and international markets.

Despite its success, the inverter was limited by the relatively short lifespan of its SMF battery, which often failed within a year or two. This challenge hindered the product’s long-term viability, particularly in regions where replacement batteries were difficult to obtain.”

Sales Ka Bazigar TV program based on hunt for sales people without the MBA degree

I conceived and produced ‘Sales ka Bazigar,’ a successful talent show aired on ETV. This show played a pivotal role in enhancing Su-Kam’s brand recognition in the North Indian states.

I personally scouted for talented individuals at various exhibitions and events, ensuring a diverse and engaging pool of contestants. The show’s popularity attracted significant sponsorship from major brands.

‘Sales ka Bazigar’ not only showcased exceptional sales talent but also provided valuable exposure and networking opportunities for participants.”

Elevating Corporate Governance: Su-Kam’s Board

I strengthened Su-Kam’s corporate governance by establishing a distinguished board of directors. Mr S. B. Ganguly, former chairman of Exide, and Mr Biplab Majumdar, MD and chairman of ABB India, were instrumental additions.

These board meetings proved to be invaluable learning experiences. I gained firsthand knowledge of conducting effective board meetings and the critical role of internal audits. Interacting with such accomplished leaders provided invaluable insights that continue shaping my business approach.

Looking back, I recognize the exceptional opportunities for growth and learning that have been bestowed upon me.”

Battery Tester for Testing of the Lead Acid battery

To address the widespread issue of substandard batteries, we developed BatteryScopie, a comprehensive battery testing instrument. This innovative device, designed to work with a computer, accurately assesses battery health, capacity, and performance.

BatteryScopie offers a valuable solution for both battery manufacturers and distributors, who often struggle to evaluate battery quality and remaining capacity. By providing precise data, BatteryScopie empowers users to make informed decisions and reduce the risk of purchasing defective batteries.

While the BatteryScopie was a promising development, its full potential was hindered by other commitments and resource constraints. Despite its potential to revolutionize the battery testing industry, the project ultimately remained incomplete.”

IoT-based Inverters and UPS:

Su-Kam has encountered significant challenges that have resulted in missed opportunities in the rapidly evolving fields of IoT and battery testing. These challenges have primarily stemmed from a combination of difficulties in fostering effective research and development (R&D) collaborations, as well as obstacles in successful market penetration. Our ambitious efforts to innovate and create cutting-edge products, such as Bluetooth-enabled inverters and home Uninterruptible Power Supplies (UPS), along with a highly anticipated battery equalizer, have not progressed as anticipated. Both internal organizational issues and external market dynamics have proven to be major hurdles that have hindered our progress.

Despite our hard work in establishing a successful YouTube channel, which has allowed us to engage with our audience and showcase our innovative approach, we have still faced considerable difficulties in bringing our novel products to market. A significant factor contributing to these challenges has been the absence of a robust and self-sustaining R&D culture within our organization. Moreover, we have struggled with effectively training and motivating our teams to push the boundaries of innovation, which has further compounded our setbacks.

On a more positive note, our grid-feed technology project has seen some level of achievement; however, this success has unfortunately been overshadowed by the overwhelming dominance of Chinese manufacturers in the global market. Their competitiveness and established presence have made it increasingly difficult for us to carve out our own niche. Additionally, the seismic shift towards grid-tied solar systems has further diminished the relevance of off-grid solutions, making it a challenge for us to align our product offerings with contemporary market needs.

In summary, while we have made strides in certain aspects of our operations, the convergence of these multifaceted challenges has limited our ability to fully capitalize on the opportunities presented by IoT technologies and battery testing advancements. Moving forward, it is crucial for us to realign our strategies and enhance our R&D capabilities to better position ourselves in a market that is growing increasingly competitive and intricate.

Filing of Technology and Design Patents

“Su-Kam’s commitment to innovation led to filing numerous technology patents, resulting in six granted patents during my tenure. Our pioneering development of sine wave technology in 2002 played a crucial role in transforming the inverter industry.

Despite the clear advantages of sine wave technology, including reduced noise and improved appliance compatibility, market resistance persisted. Competitors facing higher failure rates with their square wave inverters actively promoted the outdated technology.

While we successfully dominated the export market with our superior sine wave inverters, domestic competition remained fierce. The misconception that square wave technology was more reliable hindered our efforts to transition the Indian market fully.”

international Joint Ventures

During my tenure, I tried to do a lot of joint ventures, but somehow my luck would have it not a single joint venture work out, so I would like to put on record for the same. Each joint venture has a story, but I will try to be crisp and short on this. I will write more on each joint venture in detail once I get time.- First was to tie up with GE Power to sell their UPS in India

- Joint venture with Israel company Gamatronic to manufacture Online UPS in India

- Trojan Battery USA, which is one of the largest Lead Acid battery manufacturers and specializes in the Golf Cart batteries.

4. Kohler Generators of USA, and you can see the picture of Mr David

Kohler, who was in India to meet me personally and wanted to invest in Su-kam then.

Emerging technologies USA for making E rickshaw motors and DC Generators in India

Employees Training and Motivation Activities

Employee Meets and Training

“Su-Kam prioritized employee development through comprehensive training programs. We conducted regular training sessions, both in-house and at external venues, covering technical skills, sales techniques, and motivational topics.

Annual events like ‘Manthan’ fostered camaraderie, team building, and strategic planning. These gatherings brought together employees from all departments and locations, promoting unity and shared purpose.

The Soul of the Brand: Su-kam Was My Everything

For me, Su-kam wasn’t just a company; it was etched into my mind and my very soul. It was everything. My obsession with the brand went beyond business strategy—it was a personal devotion. At home, our towels were branded Su-kam, and even the cutlery bore the etched logo.

I never wore fashionable branded T-shirts; my absolute preference was always to wear Su-kam branded shirts. I was simply mad about this brand.

My vision was singular: I wanted to see Su-kam boards everywhere, etched into people’s minds no matter where they went—on highways, at tourist spots, or on a religious pilgrimage. The goal was to ensure the brand’s presence was inescapable. Today, I realize how all-consuming that passion was.

Strategy: Branding as Lifeblood

This obsessive focus was the engine behind Su-kam’s remarkable success. Our deliberate, strategic branding approach didn’t just boost visibility; it shaped the very perception of the brand among consumers and the industry.

Service Vans: Moving Billboards. Our service vans, distinctively adorned with Su-kam branding, did double duty. They were practical tools for service delivery, but more powerfully, they were moving billboards that constantly reinforced our image of quality and reliability in the minds of our customers.

Challenging Perceptions: We launched a well-executed, targeted advertising campaign specifically to challenge the outdated idea that Su-kam only made small inverters. By strategically showcasing our diverse, larger product range, we successfully repositioned the brand as a versatile, comprehensive power solution provider. This was crucial for market expansion.

Total Visibility: My personal attention to detail was unwavering. I ensured Su-kam signage was prominently displayed in strategic locations across India. This commitment to visibility was about solidifying our brand recognition and embedding Su-kam as a trusted industry leader.

High-Impact, Creative Branding Moments

We didn’t just advertise; we created indelible moments that captured attention:

The Banaras Car Rally: I vividly recall organizing a powerful car rally in Banaras, featuring 100 vehicles proudly covered in Su-kam branding. The sight of this fleet created a striking, lasting impression on the local community, demonstrating scale and commitment.

Shikaras of Srinagar: During a visit to Srinagar, I saw that the traditional Shikaras (boats) were financially struggling. I seized the opportunity to brand all of them with Su-kam logos, providing them with necessary funds. Years later, seeing major corporations like Airtel adopting similar Shikara branding strategies validated the effectiveness of that bold, community-focused approach.

Internal Grandeur: Our employee and dealer meets were executed on a grand scale. When we rented a venue, we visually transformed the hotel with branding elements so thorough that anyone visiting knew a major Su-kam event was happening. This professionalism embedded the Su-kam name in the consciousness of all attendees.

Vision and Foresight in Advertising

I often pushed my team beyond their comfort zone with visionary moves:

The 10KVA Statement: I initiated a bold newspaper advertisement proclaiming: “Running 3 Air Conditioners on a 10KVA Inverter.” My team wanted to stick to advertising smaller, currently popular inverters, but I was steadfast. I understood the long-term benefit of positioning the brand at the high-end of the market. To my deep satisfaction, two years later, a competitor began using the exact same slogan, which validated my strategic foresight.

The Challenge of Execution: A persistent challenge was that my employees often lacked understanding of new branding initiatives at the outset. They gradually recognized the tangible benefits as the results came in. I engaged with countless advertising companies, but only a handful offered simple, effective ideas. Many others presented grand, complex concepts that rarely translated into effective action.

Reflecting on this journey, I recognized that finding the right advertising agency and a truly skilled internal marketing team was perhaps the most formidable and recurring challenge of my career. While firms delivered dazzling pitches, their actual execution often fell short. Nonetheless, every step of this fervent branding journey has contributed to what I believe is a lasting legacy for Su-kam—a brand built on devotion and relentless visibility.

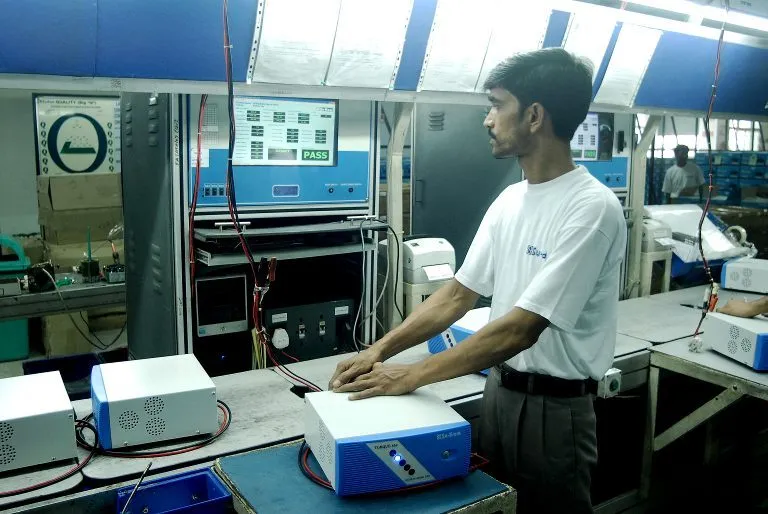

Creation of Export business from India

Export business

When I started the export business from India than there was a craze of foreign goods in India, and we used to think in India that India can export garments and handicrafts and outside India there was a same image and software industry was just coming and didn’t create any impact at that time and we were importing most of the electronics from outside and there was no question that India can export Electronics. In my industry there was no one who could dare to dream of exports. Today most of the big companies are exporting because of my initial efforts and creating a brand for India.

The first export to SriLankan in 2003 and export which we did and it was the first export for our company, and the papers made to export were wrong by our Inverter department as no one knew what documents to make and what is the importance of Inverter, but anyhow we started exports with SriLankan and after that, I focused my energies on exports, and we made a small team and personally went to countries like Nigeria and Kenya in the first phase, and it was a horrible experience to start with as Nigerians was a tough country and I carried the Inverter with me while traveling for the first time so I was not allowed to release the Inverter which I brought with me, and the corruption level was very high at that time, but somehow I clicked with one person who had a position in Nigeria and he installed my Inverter with a car battery and that’s how the Journey started in Nigeria where the person made a lot of money by selling inverters directly to the customer, and he was getting the inverters through the Air route rather than sea route and the quantity was small but he was getting good margins and demand started increasing slowly and he didn’t have money to order for a container and then so many people began asking for distributor ship and we made one strong party as our distributor and went personally to visit 4 states in Nigeria with him and travelling inside the Nigeria was tough and the planes were poorly managed and the way people boarded the plane is like people board the buses in small city and accessible for all so it was a very different experience for me but people gave me so much of respect being the inverter manufacturer from India. Slowly, we started with other countries as well, and the team consisted of service guys who supported the distributors in installation, training, and repairs, as sending them back for repairs was impossible.

Once we started exporting, we learned much about quality standards, packaging, etc., as the product couldn’t return for repairs. Once the product failed, the brand’s reputation and the distributors suffered. Lots of complaints were there initially, and we realized there were better ways to do it, so we sent people to each country with a service background and asked them to stay there for an extended period. That worked well for distributors and us. Buses branding for employees and how I learned all good and bad experiences.

Tried hard to sell UPS to take on the foreign players.

I was the first to create a YouTube channel named Su-kam Solar, and today, its videos have reached a million views. I left Su-kam in 2018, and at that time, there were more than 1 lakh followers. Nobody thought at that time that digital media would take over print and television, but I knew it, and I was ahead of my time.

Su-Kam Solar brand creation

We launched a new brand identity, Su-Kam Solar, to differentiate our solar products. This rebranding initiative included a new logo, website, and product designs featuring a distinctive yellow colour scheme.

The visual changes were instrumental in shifting Su-Kam’s perception from an inverter brand to a comprehensive solar solutions provider. Our competitors quickly recognized the effectiveness of this strategy and began incorporating similar elements into their branding.

This demonstrates Su-Kam’s influence on the industry and our ability to set trends. Our commitment to innovation and branding has solidified our position as a leader in the solar market.”

On one of my visits to Srinagar, I saw that Shikaras were in bad shape and needed more money to cover them shikaris adequately. I converted all the Shikaras to Su-kam. Later on, I realized that Airtlel and other companies followed the same strategy, and they overtook Shikara branding in Kashmir in a big way. The employee meets, and dealer meets branding was done on a big scale. If we used to hire a hotel for any meeting, then that hotel was full of branding, and anyone visiting that hotel would know that some big event was happening and the brand was itched in the minds of people.

Unique Trolley design for big Inverter Installations

We designed one trolley that can be combined to look like a single trolley in Plastic. But, unfortunately, the batteries seemed very shabby when we were installing our 10,20KVA inverters.

The trolley bank could be converted to look like single trolley banks in Plastic, and one could add as many as possible so that when batteries are kept, they look good as one stack. This project was done with one of my vendors Bhurji Electronics whose owner took a lot of interest in designing and manufacturing the trolley. And many changes were done over a while, but my team still needs to sell that in sizable nos.

Developed tread Mill in year. 2003

The Solar Projects

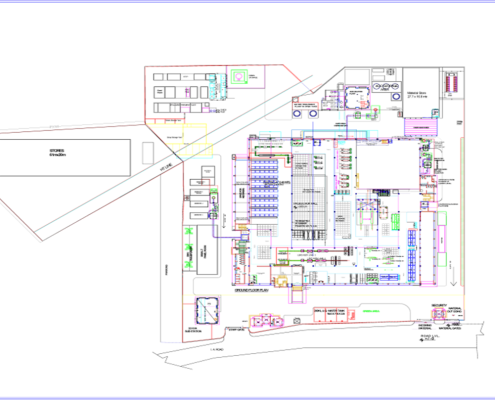

I started the Solar project division, where we were one of the pioneer companies to install megawatt projects. I got selected people who didn’t have any solar background, as solar was non-existent then, and started bidding for projects. So we initially got the SECI first phase 2 MW allocation for installing Solar projects and started installing Solar projects one by one.

Su-Kam played a pioneering role in the Indian solar industry, executing several large-scale projects, including the Punjab Engineering College and the Chennai Metro. These projects presented unique challenges, such as shadowing issues and project scope changes, which we overcame through perseverance and adaptability.

While working on the IFFCO headquarters project, we encountered a setback involving theft of project materials. Despite this incident, we successfully completed the installation and gained valuable insights into project management and security protocols.

Our expertise in solar installations for commercial and industrial applications, including car sheds, positioned Su-Kam as a trusted partner in the Solar Industry.

SBI Academy Gurgaon has a training facility for the SBI, and we solarized the whole building and saved the electricity bill almost 70% of the consumption University. We made a car park as a solar shed and utilized the Energy to reduce the power bill in the University. And it shielded the car parking and multiple uses of the space. Another project we did at Rani Polymers where we proved to them that electricity saving could reduce the bill and this power is genuinely cheaper than Utility Power. When we were installing these projects, there were hardly any prominent players, and we got a lot of experience. We kept increasing the team and training the people as hardly any people were in the solar project field.

And solar Energy is stored in the same batteries, and the output is standard for the load as this was around a coastal area, so

we were supplied by a Pune supplier. The rest were provided by us in 2010, and we made a standard Electronics wind energy.

One could get bioenergy through solar and wind both. This project is working even today as we reached the experience of running wind and solar together, and we also tried one of these projects in India.

I duplicated this project at my farmhouse as well, where there was a windmill was windmill and solar. Both were working as I see this as the future of many countries, including India.

I visited this site personally for this project and was very proud to execute this project outside India.

This was the Up govt project called Lohia Vikas, where we installed DC systems. There was no light in these houses, and the light was provided through the DC system having a capacity of 100 watts, and this had the facility to run one fan and two lights and mobile charging facility. Making the DC system for this project was a big challenge as it was time bound. We designed the product in time and was approved by the approving agency, executed the project almost in time and installed it in different remote villages of the UP. We made teams who could go and install it remotely, and we also tried to outsource the project to two agencies. Still, we had a bad experience as they were very slow, and in some cases, our material used to get stolen, as getting the project done and getting out the money was another challenge we faced. This project has caused us a loss to the company. There were five years of maintenance, and our service people made money by claiming batteries from the company and other stuff. Handling engineers remotely was stressful as the management was done correctly. As the company increased, the HR department remained unstable as whoever became the HR head; performance was significantly below average. I can say that company was growing quite haphazardly. We could not create systems and processes as my involvement in RnD sales and marketing was the highest. I thought anyone could see the HR, which was a big mistake as my interest in finance was also missing, so the company’s finances were also very loose.

Arunachal Pradesh was the first north East solar project done of 600KW grid feed, and this was our very successful project in the Northeast as we did several projects in the Northeast covering all seven states.

This is the Assam Rifles Grid project, where we installed it in 7 different locations in the Northeast. It was done in a joint venture of REIL, a Rajasthan State Govt company, and 100 and 150 Kw off-grid solar projects were done. The REIL and the rest batteries supplied by the solar panels and Electronics were provided and installed by us. We designed the remote monitoring system as well for these seven projects. So this was a very successful project where we installed these systems. There was a massive benefit to the Assam Rifles as taking the diesel to these far-flung areas was very tough and costly. So we made this system successful, where they hardly used diesel generators after installing the solar off-grid system. We got two distributors also during the installation of these projects in the Northeast.

The Mini-Grid 250KW project at UP had three installations done by us, which was very challenging as there was no electricity in that area. State Govt connected 5 to 6 villages through this 250KW project, and the execution of this project was a tremendous task as we had to distribute the power. Power was free for people, and everyone wanted more and more power. They installed the new fans and lights in their homes and were given only a 100 W connection for each home. We had put the load controllers for that purpose, but people came to know of that. They made direct connections, and all the pumps for irrigation purposes were running on this. People kept increasing the pumps, and the battery bank was installed for three days of backup in case no solar was available. The batteries started giving us problems as this system was overloaded, and controlling the people in that area was next to impossible. Villagers had fights with our people daily, and no staff was ready to stay there as this project we were to maintain for five years, so we kept struggling as our people kept changing at the site, and all three areas had significant issues with maintenance. We were the early people to learn to install the off-grid Mini project in India. Other projects also came along similar lines, but we didn’t bid for them.

We made a unique solar panel trolley for the Indian army and a movable Inverter truck so that Army can open the Solar panels anywhere while travelling, get solar power, and run the equipment. this project took more than 1 year to make ready, and Army officials are here to inspect the system in the below pictures.

Solar Project Division

Su-Kam was a pioneer in the development of DC-based solar inverters, offering a more efficient and cost-effective solution compared to traditional AC systems. We successfully implemented these inverters in various projects, including a significant deployment for low-income homes in Uttar Pradesh.

While the DC inverter technology was a breakthrough, challenges in government payments and intense competition from other solar companies contributed to Su-Kam’s financial difficulties. The lack of understanding regarding the reasons for our financial struggles led to an unfair assessment and ultimately contributed to our bankruptcy.

I advocate for a more nuanced approach to evaluating struggling companies, considering factors beyond financial performance. A system that encourages rehabilitation and supports entrepreneurship could have prevented unnecessary liquidation.”

Solar Projects Brochure

The major Decision to convert Service Employees to Outsourcing of Services for the Company

Su-Kam’s service department faced significant challenges, including high turnover, inefficiency, and fraud. Despite our efforts to address these issues through training and development, we were unable to create a sustainable and high-performing service team.

To overcome these obstacles, we implemented a groundbreaking strategy: outsourcing our entire service function. By offering incentives and support to our existing service engineers, we encouraged them to become independent service providers.

This innovative approach not only reduced our operational costs but also fostered a more competitive service market. The success of this model inspired other companies to follow suit, demonstrating its effectiveness in improving service quality and efficiency.”

The Collapse: Corporate Betrayal and Personal Crisis

As I battled the devastation of Su-kam’s bankruptcy, I was dealing with a tough personal challenge—a divorce. But the truth is, the pressure from the corporate side—the involvement of the Reliance Anil Ambani Group—cost me far more, both financially and emotionally, than my personal struggles.

The Reliance Anil Ambani Group had taken over the fund that was a joint venture with Temasek Holdings, a global investment company owned by the Government of Singapore. I had hoped for stability, but what I got was chaos.

The Problematic Partner

The main issue was their attitude and their constant, disruptive meddling. They treated their role not as investors but with the rigid, detached style of a government bureaucracy.

Constant Instability: They changed their representative Director on the Su-kam board every six months. This continuous turnover meant zero consistency and prevented any strategic long-term planning.

The Wedge: They appointed an ex-Indian Revenue Service (IRS) officer named V. K. Tripathi to the board. His presence immediately created tension. He quickly began trying to drive a wedge between me and my elder son to make him director on the board of Su-kam for which I was not ready as he was not having enough experience and knowledge and we had a distinguished board of eminent people created under my leadership.

Political Pressure: Tripathi was adamant about to ring this change immediately. I was clear that he needed to achieve specific business milestones before that promotion could happen. He ignored this and began playing internal politics on the board, constantly fighting with my leadership team.

The Forensic Audit and Panic

Out of frustration and spite, V. K. Tripathi took a devastating action: he unilaterally ordered a forensic audit of Su-kam through one of the ‘Big Four’ auditing firms.

This was the moment the hell broke loose.

The initiation of a massive, public forensic audit instantly signaled trouble to our lenders. It became one of the major reasons the banks went into panic mode, sealing the fate of the company and accelerating the bankruptcy process. It was a self-inflicted wound, caused entirely by the destructive internal politics of our partners.

Looking back, the irony is painfully sharp: The very group that destabilized my company, the Reliance Anil Ambani Group, eventually faced its own downfall and went bankrupt as well. Their actions, driven by a dysfunctional, arrogant style of management, directly contributed to the destruction of Su-kam.